Learn Design and Simulation of chemical plants and equipment

Loại khoá học: Engineering

Learn from chemical industry expert. Enhance you market value.

Mô tả

Introducing Learn Design and Simulation of chemical plants and equipment from Industry Expert.

Are you ready to take your skills in chemical engineering to the next level? Look no further! We are thrilled to present our comprehensive online course on Design and Simulation of chemical plants and equipment. Whether you're a seasoned professional or a student aspiring to enter the industry, this course is designed to equip you with the knowledge and skills needed to excel in the field.

Why learn design and simulation in the chemical industry? The answer is simple: it is the backbone of modern chemical engineering. Simulation allows engineers to predict and optimize process behavior, minimize risks, and improve efficiency. By understanding the principles and techniques of design and simulation, you gain a competitive edge and open up a world of possibilities in your career.

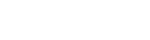

In this course, we delve into the key concepts and methodologies of design and simulation. We start by exploring the fundamentals, differentiating between design and simulation and discussing their respective roles in chemical engineering. We then explore two fundamental approaches: phenomenological model-based simulation and data-driven machine learning-based simulation. By understanding the advantages and disadvantages of these approaches, you will be able to choose the most suitable method for different scenarios.

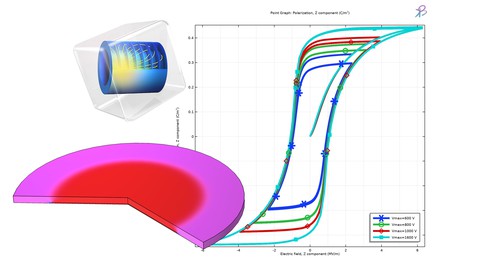

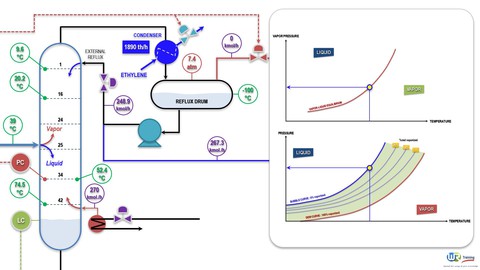

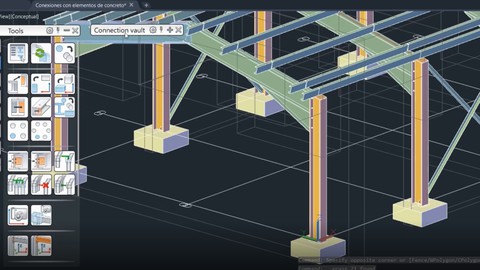

We take a hands-on approach, utilizing Aspen, a leading simulation software widely used in the industry. You will be guided through various simulations, starting with property analysis, flash drum simulation, pump and pipeline simulation, heat exchanger simulation, and reactor simulation. We cover both basic and advanced simulations, including plug flow reactors, CSR, batch reactors, industrial ethylene glycol and ethyl acetate reactors, and more.

A significant portion of the course is dedicated to distillation column simulation. You will gain an overview of different distillation column models available in Aspen, including DSTWU and Radfrac rigorous distillation simulations. We also provide a comprehensive case study involving six distillation column simulations, including an industrial benzene column simulation. Additionally, we explore how to identify the optimum feed tray location, and we introduce the exciting topic of simulation by machine learning, discussing its relevance and the steps involved.

Speaking of machine learning, we delve into its foundations, understanding the key terms and concepts. You will learn how to clean data, detect outliers, handle missing values, and encode data for machine learning purposes. We guide you through the steps of developing a data-driven regression model, including model selection and performance evaluation. Through engaging case studies, such as bioreactors and soft sensors in distillation columns, you will witness the practical application of machine learning in simulation.

Course Content: Design and Simulation of chemical plants and equipment

Section 1: Introduction

· Why learn design and simulation in the chemical industry?

· Understanding the concept of simulation

· Differentiating between design and simulation in chemical engineering

Significance: This section provides an overview of the course, highlighting the importance of design and simulation in the chemical industry. It sets the foundation for understanding the subsequent topics and their practical applications.

Section 2: Two Fundamental Approaches of Modeling and Simulation

· Phenomenological model-based simulation and its advantages and disadvantages

· Data-driven machine learning-based simulation and its advantages and disadvantages

Significance: This section introduces the two fundamental approaches to modeling and simulation in chemical engineering, allowing learners to understand the strengths and weaknesses of each method. It helps learners make informed decisions about choosing the appropriate approach for specific scenarios.

Section 3: Aspen-Based Simulation

· Walkthrough of the Aspen software interface

· First Aspen-based simulation

Significance: This section familiarizes learners with the popular Aspen simulation software, providing hands-on experience in navigating the interface and conducting their first simulation. It builds confidence and prepares learners for more advanced simulations throughout the course.

Section 4: Property Analysis

· Understanding the property analysis quick method assistant

· Pure component property analysis

· Property analysis of binary mixture

Significance: Property analysis is a crucial step in chemical engineering design and simulation. This section guides learners in analyzing properties efficiently, ensuring accurate simulation results. It covers both single-component and binary mixture analyses.

Section 5: Flash Drum Simulation

· Separated simulation

Significance: Flash drum simulation is commonly used in chemical processes. This section covers the simulation of flash drums and explores separated simulation techniques, providing learners with practical knowledge in simulating and optimizing these operations.

Section 6: Pump and Pipeline Simulation

· Simulating pump and pipeline systems

Significance: Pump and pipeline systems are integral components of chemical processes. This section teaches learners how to simulate and analyze these systems, considering factors such as pressure drop, flow rates, and efficiency.

Section 7: Heat Exchanger Simulation

· Simple heat exchanger simulation

· Rigorous heat exchanger simulation

Significance: Heat exchangers play a vital role in energy transfer within chemical processes. This section covers both simplified and rigorous heat exchanger simulations, enabling learners to optimize heat transfer and improve process efficiency.

Section 8: Reactor Simulation

· Plug flow reactor simulation

· CSR simulation

· Batch reactor simulation

· Industrial ethylene glycol reactor simulation

· Gibbs reactor simulation

· Industrial ethyl acetate reactor simulation

Significance: Reactor simulation is crucial for understanding chemical reactions and optimizing reactor designs. This section covers various reactor types and their simulations, allowing learners to analyze reaction kinetics, conversion rates, and select the appropriate reactor configuration for specific applications.

Section 9: Distillation Column Simulation

· Overview of different models of distillation columns available in Aspen

· DSTWU module

· Radfrac rigorous distillation simulation

· Case study of 6 distillation column simulations, including an industrial benzene column simulation

· Identifying optimum feed tray location

Significance: Distillation is a widely used separation technique in the chemical industry. This section explores different distillation column models and simulations, including rigorous distillation simulations. Learners gain insights into optimizing column design, tray location, and achieving desired separation efficiency.

Section 10 : Simulation by Machine Learning

· Case study of bioreactors simulation by machine learning

· Steps to develop a machine learning model

· Regression learner tools

· Data preparation for machine learning

· Model selection for machine learning simulations

· Performance evaluation of the developed model

· Visualizing simulation results

Significance: This section explores the application of machine learning in simulation. Learners will understand when and how to utilize machine learning techniques for simulation purposes. The case study on bioreactors demonstrates the practical implementation of machine learning models in chemical engineering processes. Learners will gain insights into data preparation, model selection, performance evaluation, and result visualization, enabling them to apply machine learning effectively in their own simulations.

Section 11: Case Study to Develop a Soft Sensor in Distillation Column

· Developing a soft sensor using simulation data

· Understanding the role of soft sensors in distillation columns

· Practical implementation of a soft sensor for real-time monitoring and control

Significance: Soft sensors play a crucial role in distillation column operations, providing real-time monitoring and control. In this case study, learners will learn how to develop a soft sensor using simulation data and understand its significance in optimizing distillation processes.

Section 12: Case Study: Industrial Catalytic Reactor Simulation

· Simulation of an industrial catalytic reactor

· Analyzing reaction kinetics and reactor performance

· Optimization of operating conditions for improved productivity

Significance: This case study focuses on simulating an industrial catalytic reactor, allowing learners to explore reaction kinetics, reactor performance, and the optimization of operating conditions. Learners will gain practical knowledge in simulating and improving the efficiency of catalytic reactors.

Conclusion:

This comprehensive online course on Design and Simulation in Chemical Engineering covers essential topics, techniques, and case studies to equip learners with the knowledge and skills needed to excel in the field. By understanding the principles of design and simulation, as well as gaining hands-on experience using industry-standard software and machine learning techniques, learners will be well-prepared to tackle real-world challenges in chemical engineering. Enroll in this course today and embark on a journey of professional growth and mastery in design and simulation.

Join us on this exciting journey as we equip you with the skills to design and simulate chemical engineering processes effectively. Our expert instructors bring years of industry experience and a passion for teaching, ensuring that you receive top-quality instruction and guidance throughout the course. Take the first step towards mastering design and simulation in chemical engineering and enroll in our course today!

Bạn sẽ học được gì

Whether you're a seasoned professional or a student aspiring to enter the industry, this course is designed to equip you with the knowledge and skills .

In this course, we delve into the key concepts and methodologies of design and simulation.

We start by exploring the fundamentals, differentiating between design and simulation and discussing their respective roles in chemical engineering.

We then explore two fundamental approaches: phenomenological model-based simulation and data-driven machine learning-based simulation.

We take a hands-on approach, utilizing Aspen, a leading simulation software widely used in the industry.

Speaking of machine learning, we delve into its foundations, understanding the key terms and concepts.

Yêu cầu

- Preliminary knowledge of Aspen and Matlab is desirable bt not neccessary.

Nội dung khoá học

Viết Bình Luận

Khoá học liên quan

Đăng ký get khoá học Udemy - Unica - Gitiho giá chỉ 50k!

Get khoá học giá rẻ ngay trước khi bị fix.

Đánh giá của học viên

Bình luận khách hàng