Flow of fluids through piping systems , valves and pumps

Loại khoá học: Industry

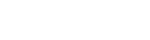

Learn to size valves & piping systems, calculate pressure drop, flow of liquids & gases through pipe , fittings & valves

Mô tả

The most diverse substances are transported and distributed in piping systems every single day. They include aggressive fluids in the chemical industry, hydrocarbons in petrochemistry or steam for energy transmission.

Chemical engineers who are designing these piping systems and specifying associated equipment like valves, pumps and flow meters probably face more fluid flow problems than any other. Pressure drop calculations help the engineer size pipes and ducts, determine performance requirements for pumps and fans, and specify control valves and flow meters. And although the underlying theory is rather simple, its practical application can be confusing due to the empirical nature of important correlations, multiple methods for expressing parameters, many variable inputs, and alternative units of measurement.

Designed around a series of practical examples which we work through to a solution, this unique training course is an essential guide to understanding the flow of fluids through pipe, valves and fittings. This understanding is a prerequisite for a successful design & flawless operation of your plant and piping system.

The course features 5 major items :

1- An in-depth information on physical properties of fluids (weight density, specific gravity, viscosity, vapor pressure...) and how to calculate them using Flow of Fluids Excel Workbook

2- An in-depth information on compressible and incompressible fluid flow through piping systems, valves, pumps & flow meter devices (Orifice plates, Flow Nozzles & Venturi Meters) and how to calculate them using Flow of Fluids Excel Workbook

3- An iterative method for sizing flow meters and valves

4- An in-depth discussion on cavitation and choking in control valves

5- A flow problem section with 25 concrete examples to help you practice and reinforce your understanding

Many images, equations, graphs, 3D animations and solved flow problems can be found throughout, increasing the value of this course as an educational tool and industrial reference for personnel involved in the fluid handling industries.

So this course is not only of use to practising and professional engineers to whom a knowledge of the behavior of fluids is of crucial importance in cost-effective design and efficient operation of process plants and piping systems but also intended as a study guide for undergraduates in process, chemical, petrochemical & petroleum engineering disciplines.

So with no further ado, check out the free preview videos and the curriculum of the course and we look forward to seeing you in the first section.

Hope to see you there

WR Training

Spread the wings of your knowledge

-

Important note about Flow of Fluids Excel Workbook

To accompany this course and help you assess flow of fluids, calculate pressure drops, size pipes, control valves and flow meter devices, WR Training has developed an Excel VBA based engineering tool : Flow of Fluids Excel Workbook.

Flow of Fluids Excel Workbook simulates the operation of small piping systems transporting liquids and industrial gases under a variety of operating conditions.

Flow of Fluids Excel Workbook is based on industry recognized principles and standards from ASME, HI, IEC, AWWA, ISA, and ANSI

Flow of Fluids Excel Workbook is easy-to-use and has a highly intuitive user interface.

Flow of Fluids Excel Workbook presents formulas and data for :

1. Physical properties determination for a variety of fluids (specific gravity, viscosity, vapor pressure)

2. Pressure drop and head loss calculations through pipes, fittings and valves

3. Flow calculations for incompressible and compressible fluids through piping systems, fittings, valves and pumps

4. Sizing piping systems for incompressible and compressible fluids

5. Flow resistance coefficients calculations for pipes, fittings and valves

6. Flow calculations for incompressible and compressible fluids through flow meters (Orifice Plates, Nozzles and Venturi meters)

7. Centrifugal pump calculation (Pump head, NPSH, Specific speed, affinity laws)

8. Converting variables and process parameters to a numerous alternative units of measurement

-

Flow of Fluids Excel Workbook: Table of content

a. physical properties of fluids

1 properties of water and steam

a. saturation properties with temperature

b. saturation properties with pressure

c. properties given pressure and temperature

d. properties given pressure and enthalpy

2 dynamic viscosity of gases

3 kinematic viscosity

4 weight density of liquids

a. formula 1

b. formula 2

c. formula 3

5 specific gravity of liquids

a. formula 1

b. formula 2

6 specific gravity - deg api

7 specific gravity - deg beaume

8 specific volume

9 weight density of ideal gases

10 weight density of real gases

11 gas compressibility factor

12 specific gravity of gases

13 boiling point pure component

14 vapor pressure : pure component

15 vapor pressure : mixture

b. nature of flow in pipe

1 rate of flow at flowing condition

a. formula 1

b. formula 2

2 rate of flow (gpm)

a. formula 1

b. formula 2

c. formula 3

3 mean velocity of flow in pipe

a. formula 1

b. formula 2

c. formula 3

4 reynolds number

a. formula 1

b. formula 2

c. formula 3

d. formula 4

e. formula 5

f. formula 6

g. formula 7

c. bernoulli's theorem

1 total head or fluid energy

2 loss of static pressure head (hl) due to fluid flow

d. head loss, pressure drop and friction factor through pipe

1 loss of static pressure head

a. formula 1

b. formula 2

c. formula 3

d. formula 4

e. formula 5

f. formula 6

2 pipe pressure drop

a. formula 1

b. formula 2

c. formula 3

d. formula 4

e. formula 5

f. formula 6

g. formula 7

3 pressure drop for laminar flow according to poiseuille's law

4 pressure drop for turbulent flow according to hazen-williams formula

5 friction factor for laminar flow

6 friction factor for turbulent flow

a. colebrook equation

b. serghide equation

c. swamee-jain equation

e. gas calculations

1 perfect gas law

a. determining the number of moles of a perfect gas

b. determining the pressure of a perfect gas

c. determining the temperature of a perfect gas

d. determining the volume of a perfect gas

2 non-ideal gas law

a. determining the number of moles of a non-ideal gas

b. determining the pressure of a non-ideal gas

c. determining the temperature of a non-ideal gas

d. determining the volume of a non-ideal gas

3 standard ◄►actual gas flow

f. compressible flow in straight horizontal pipeline

1 complete isothermal equation

g. gas pipelines : mass flow rate equation

h. horizontal gas pipelines : standard volumetric flow rate equations

1 general standard volumetric flow rate

2 weymouth standard volumetric flow rate equation for sizing horizontal gas pipelines in fully turbulent flow

3 panhandle "a" standard volumetric flow rate equation for sizing horizontal gas pipelines in partially turbulent flow

4 panhandle "b" standard volumetric flow rate equation for sizing horizontal gas pipelines in fully turbulent flow

i. elevated gas pipelines : standard volumetric flow rate equation

j. liquid flow through orifices

k. liquid flow through isa 1932 nozzles

l. liquid flow through long radius nozzles

m. liquid flow through venturi nozzles

n. liquid flow through venturi meters

o. gas flow through orifices

p. gas flow through isa 1932 nozzles

q. gas flow through long radius nozzles

r. gas flow through venturi nozzles

s. gas flow through venturi meters

t. resistance coefficient for pipes, valves and fittings

1 contraction

2 enlargement

3 gate valves

4 globe and angle valves

5 swing check valves

6 lift check valves

7 tilting disc check valves

8 stop check valves

9 foot valves with strainer

10 ball valves

11 butterfly valves

12 diaphragm valves

13 plug valves

14 mitre bends

15 90° pipe bend and flanged or bw 90° elbows

16 multiple 90° pipe bends

17 close pattern return bends

18 standard elbows

19 pipe entrance

20 pipe exit

21 tees and wyes - converging flow

22 tees and wyes - diverging flow

23 orifices, nozzles and venturis

u. head loss and pressure drop through valves and fittings

1 loss of static pressure head

a. formula 1

b. formula 2

c. formula 3

2 pipe pressure drop

a. formula 1

b. formula 2

c. formula 3

v. flow of fluids through valves, fittings and pipe

1 liquid flow through a valve, fittings and pipe

a. formula 1

b. formula 2

c. formula 3

d. formula 4

e. formula 5

f. formula 6

g. formula 7

2 gas flow through a valve; fittings and pipe

a. formula 1

b. formula 2

c. formula 3

3 valve flow coefficient "cv"

a. formula 1

b. formula 2

4 valve resistance coefficient "k"

w. calculations for centrifugal pump

1 pump head

a. head formula

b. pump in suction head

c. pump in suction lift

2 pump discharge pressure

3 net positive suction head required

4 net positive suction head available

5 total dynamic head

6 suction specific speed (nss)

7 specific speed (ns)

x. pump affinity laws

1 impact of speed on flow

2 impact of speed on head

3 impact of speed on bhp

4 impact of impeller diameter on flow

5 impact of impeller diameter on head

6 impact of impeller diameter on bhp

7 pump brake horspower

8 pump efficiency

y. flow of water through schedule 40 steel pipe

1 calculations for pipe other than schedule 40

z. flow of air through schedule 40 steel pipe

1 calculations for pipe other than schedule 40

2 calculations for other set of temperature and pressure

3 from standard to actual volume flow

zz. conversion tables

1 length

2 area

3 volume

4 velocity

5 mass

6 mass flow rate

7 volumetric flow rate

8 force

9 pressure and liquid head

10 energy, work and heat

11 power

12 weight density

13 temperature

14 dynamic viscosity

15 kinematic viscosity

-

DISCLAIMER

This software is provided by WR Training "as is" and any express or implied warranties, including, but not limited to, the implied warranties of merchantability and fitness for a particular purpose are disclaimed. In no event shall the Copyright owner or contributors be liable for any direct, indirect, incidental, special, exemplary, or consequential damages (including, but not limited to, procurement of substitute goods or services, loss of use, data, or profits, or business interruption) however caused and on any theory of liability, whether in contract, strict liability, or tort (including negligence or otherwise) arising in any way out of the use of this software, even if advised of the possibility of such damage.

Bạn sẽ học được gì

Yêu cầu

Nội dung khoá học

Viết Bình Luận

Khoá học liên quan

Đăng ký get khoá học Udemy - Unica - Gitiho giá chỉ 50k!

Get khoá học giá rẻ ngay trước khi bị fix.

Đánh giá của học viên

Bình luận khách hàng