Geometric Dimensioning and Tolerancing (GD&T) : Basics

Loại khoá học: Other Design

Learn the essential concepts of GD&T , for mechanical and manufacturing engineers with practice exercises

Mô tả

The course is designed in a way to build from the basic concepts of engineering drawing towards more complex concepts. It starts with explaining the importance of an engineering drawing and going on to explain why GD&T the need has arisen and then a deep dive into the concepts of GD&T

If you are a total beginner the course will build progressively in terms of concepts to capture the core tenets of GD&T.

If you are a seasoned professional then the latter portions of the course will be useful to you

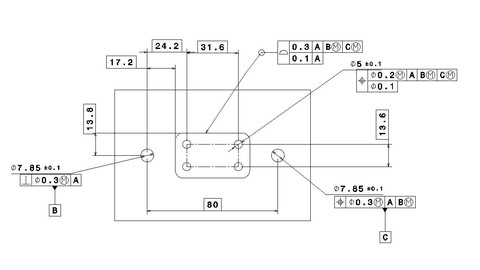

Geometric dimensioning and tolerancing is a body of knowledge and a symbolic language used to communicate design intent on an engineering drawing for manufacturing and inspection.

In this course you will learn , how exactly are the core concepts of GD&T built and how they are applied to drawings with multiple examples .

You will learn and appreciate the importance of the language over the traditional way of dimensioning and learn the possibilities of controlling the parts' variations using various combinations of symbols and controls.

The course will cover the following topics

Overall perspective of what an engineering drawing is and why it is important.

The Need for GD&T then moving towards the introductory concepts of GD&T

A comprehensive comparison of Traditional method of tolerancing vs GD&T

A detailed look at Datums the most important concept in GD&T , How are they created? How are they applied? and what do they mean on the drawing?

A detailed look at Bonus tolerance and concept of virtual condition which lays a key role in Mating parts.

Explanation of Symbols and their inspection methods

Form

Straightness

Flatness

Circularity and cylindricity

Orientation

Angularity

Perpendicularity

Parallelism

Location

Position

Symmetry and Concentricity

Runout

Profile

Finally we will have a look at the concept of Datum feature modifiers or Datum shift.

Each section has a Quiz and you will find practice exercises to practice your GD&T skills .

The course is designed in such a way that each and every point is captured as a sub topic with multiple short lectures which are to the point with condensed information.

At the end of the course, take a quiz with 30 insightful questions which will test your conceptual understanding of the subject.

Bạn sẽ học được gì

The basic concepts of Geometric Dimensioning and tolerancing

How to apply GD&T to a part drawing

Why is GD&T needed and what are its advantages over the traditional method

Practice what is learnt through thought provoking exercises with multiple problem sets in the Practice section

Reinforce concepts with 50+ Questions

Learn from a seasoned design engineer with real world experience in designing chassis systems

Yêu cầu

- Basic knowledge of mechanical engineering

- Basic awareness on engineering design

- Basic knowledge of making 2D drawings

Nội dung khoá học

Viết Bình Luận

Khoá học liên quan

Đăng ký get khoá học Udemy - Unica - Gitiho giá chỉ 50k!

Get khoá học giá rẻ ngay trước khi bị fix.

Đánh giá của học viên

Bình luận khách hàng