Know Read Understand Piping & Instrumentation Diagrams P&IDs

Loại khoá học: Industry

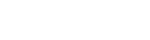

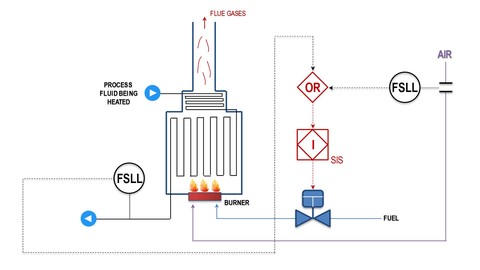

Learn how Process Control, Safety Instrumented Systems, Interlock & Alarms are represented in engineering P&ID drawings

Mô tả

Piping and Instrumentation Diagrams commonly referred to as P&ID’s are encountred nowadays throughout all process industries such as Oil & Gas, chemical, pharmaceutical or food industries.

These engineering drawings are used worldwide in design, construction, commissioning, operation and maintenance of industrial plants.

They provide clear information on processes, equipment, control systems and how the plant should handle emergency situations.

As a potential actor in these industries, it is therefore vital that you have a thorough understanding of P&ID’s components and construction.

Piping and Instrumentation Diagrams don’t have to be a complicated ! It isn’t rocket science ! This course will make you a P&ID expert and you will know how to read, interpret and successfully understand :

all of those many lines

symbols

process control schemes

and safety instrumented functions you see in your plant drawings

The knowledge gained in this course will help you to understand ALL P&ID’s so that you can draw the correct information from them.

This will set you apart from your peers, whether you are an operator, engineer, or manager and will give you an edge over your competitors when seeking employment at one of these industrial facilities.

Moreover since Piping and Instrumentation Diagrams are used in the planning and risk assessment of tasks to identify hazards, process flows and isolation points, then by ensuring that these drawings are properly drawn and understood, you contribute to the safety of your facility, your fellow workers and yourself.

This training course starts by initiating you to basic blueprint reading (which is also used in electrical, hydraulic and mechanical fields of expertise), then moves on to familiarize you with simple to complex process flow features, such as :

instrument loops

advanced process control systems

safety instrumented functions

and alarm systems

Symbols are also discussed thoroughly with all the P&ID's standards, conventions and designation codes that apply to them according to the ISA symbology. These include :

valves (gate, globe, ball, butterfly...)

actuators (pneumatic, hydraulic, solenoid, single acting spring return, double acting...)

process equipment (pumps, compressors, heat exchangers, reactors...)

instrumentation (flow meters, temperature transmitters, pressure gauges...)

piping and fittings

lines

signals (pneumatic, hydraulic, electric...)

Included in the course are access to numerous downloadable resources, real industrial examples of P&ID’s and the keys to interpret them in high quality video lectures. You will be able to practice and become even more proficient with these bonus items that you will find throughout the course.

So with no further ado, check out the free preview videos and the curriculum of the course and we look forward to seeing you in the first section.

Hope to see you there

WR Training

Spread the wings of your knowledge

Bạn sẽ học được gì

Understand and evaluate the purpose, content, and importance of P&IDs to the construction, commissionning, safe operation and maintenance of a process plant

Learn how to read, interpret and successfully understand ALL P&IDs through numerous real industrial examples

Identify the 5 key sections of your P&ID (title block, grid system, revision block, notes and legend, engineering drawing block)

Know and identify valve symbols on your P&IDs (gate, globe, ball, butterfly, needle…)

Know and identify valve actuator symbols on your P&IDs (pneumatic, hydraulic, electric, single acting spring return, double acting…)

Know the standards and conventions for valve status (open, closed, throttled)

Identify valve position and failure mode on your P&IDs (LO, LC, FO, FC, FAI…)

Know and identify process equipment symbols on your P&IDs (pumps, compressors, heat exchangers, columns, furnaces, reactors, vessels, containers, mixers…)

Know and identify piping symbols on your P&IDs (process, pneumatic, electric, hydraulic…)

Determine specific information about a process piping including type of material in the line, line size, line number and type of insulation when applicable

Know and identify pipe fitting symbols on your P&IDs (flanges, reductions, caps, spool pieces, unions…)

Know and identify the P&ID symbols of safety devices that are used to safely isolate, vent & drain process equipment for ease of maintenance (spectacle and spade blinds, double block and bleed valves…)

Know and identify pneumatic, electric, hydraulic and instrument signal lines on your P&IDs

Know and identify instrumentation symbols on your P&IDs (flow meters, temperature transmitters, pressure gauges…)

Know and identify the location of instruments, recorders, modifiers and controllers on your P&IDs (field mounted, board mounted, inaccessible…)

Know the lettering and numbering standards based on ISA symbolgy for piping, instruments and equipment designation on your P&IDs

Trace the flow of a process stream into your P&ID, through the pipes and equipment, and out of the P&ID

Understand the importance of process control and how it is displayed on your P&IDs

Successfully interpret basic process control schemes on your P&IDs

Understand the different process control options and how they are displayed on your P&IDs (cascade control, split range control, ratio control, batch control, selective control…)

Define the term Flow Control and explain how it is displayed on your P&IDs

Define the term Temperature Control and explain how it is displayed on your P&IDs

Define the term Pressure Control and explain how it is displayed on your P&IDs

Define the term Level Control and explain how it is displayed on your P&IDs

Understand the control of pressure in a pipe and explain how it is displayed on your P&IDs

Understand the control of flow in a pipe and explain how it is displayed on your P&IDs

Understand flow merging control and explain how it is displayed on your P&IDs

Understand flow splitting control and explain how it is displayed on your P&IDs

Understand centrifugal pump control systems (discharge throttling, variable speed drive, minimum flow…) and explain how they are displayed on your P&IDs

Understand positive displacement pump control systems (recirculation pipe, variable speed drive, stroke adjustment…) and explain how they are displayed on your P&IDs

Understand compressor control systems (capacity control, variable speed drive, anti-surge…) and explain how they are displayed on your P&IDs

Understand heat exchanger control systems (direct control, bypass control, back pressure control…) and explain how they are displayed on your P&IDs

Understand reactor temperature control systems and explain how they are displayed on your P&IDs

Understand fired heater control systems and explain how they are displayed on your P&IDs

Understand container and vessel control systems and explain how they are displayed on your P&IDs

Understand electric motor control systems (ON / OFF actions) and explain how they are displayed on your P&IDs

Know and understand the concept of Safety Instrumented Systems (SIS) and explain how safety instrumented functions are displayed on your P&IDs

Know and understand the concept of Alarm Systems and explain how alarms are displayed on your P&IDs

Identify safe operating limits based on system designs as displayed on your P&IDs

Know and understand how Fire and Gas Detection Systems (FGS) are displayed on P&IDs

Assess emergency situations and regulatory compliance issues using your P&IDs

Yêu cầu

- Some engineering or field knowledge is preferable but not mandatory. All the concepts are explained in depth using an easy to understand language to allow students to build their knowledge from the ground up

Nội dung khoá học

Viết Bình Luận

Khoá học liên quan

Đăng ký get khoá học Udemy - Unica - Gitiho giá chỉ 50k!

Get khoá học giá rẻ ngay trước khi bị fix.

Đánh giá của học viên

Bình luận khách hàng