Process Control & Instrumentation 16 Hour Masterclass

Loại khoá học: Industry

Know & understand process control PID controllers control valves actuators positioners & instrumentation like a pro

Mô tả

Welcome to this 16 hour masterclass on process control and instrumentation.

This valuable masterclass is organized into 6 parts :

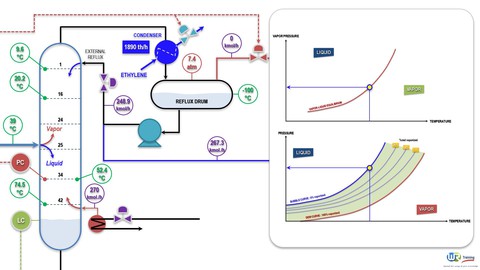

Part 1: Process Control and PID* Controllers

Part 2: The Final Control Element - Control Valves, Actuators and Positioners

Part 3: Practical Examples of Temperature, Pressure, Flow and Level Controls

Part 4: Practical Examples of Process Equipment Controls (Heat Exchangers, Pumps, Compressors, Reactors, Piping Systems…)

Part 5: Safety Instrumented Systems (SIS), Interlocks and Alarms

Part 6: Instrument Devices For Temperature, Pressure, Flow and Level Measurement

Part 1 is an essential guide to a complete understanding of process control principles and PID* controllers design and tuning. In this first module, we will break down for you all the process control principles into easily digestible concepts, like feedback controls, open loops, split range controls, self-acting controls... Useful reference data, technical recommendations, field observations and numerous process control schemes are presented in an-easy-to-understand format. This module also cautions the process control engineer that the performance of a properly designed process control system can be severely compromised when used in conjunction with incorrect PID* controller settings. In this regard, PID* controller tuning guidelines and their rationale according to the Ziegler Nicholls method are offered to ensure optimum performance. Typical tuning examples have been included to assist you in understanding how specific formulae are applied.

Part 2 focuses on the final control element of any process control system, that is the valve-actuator-positioner assembly. In this second module, you will find valuable insights into the working principles and construction details of the following control elements:

Control valves (sliding stem and rotary / fast opening, linear and equal percentage)

Mixing and diverting 3-port control valves

Diaphragm actuators ("air-to-push-up" and "air-to-push-down")

Piston actuators (Single Acting and Double Acting / Fail Open (FO) and Fail Closed (FC))

Rack-and-pinion actuators (Single Acting and Double Acting / Fail Open (FO) and Fail Closed (FC))

Scotch Yoke actuators (Single Acting and Double Acting / Fail Open (FO) and Fail Closed (FC))

Pneumatic positioners (force balance, motion balance)

Digital positioners

I/P converters

...

The module then proceeds through a series of process examples and solved problems that require you to:

Dismantle and assemble various types of control valves and actuators using 3D and 2D models

Identify the net effect of various control valve/actuator assemblies (direct acting, reverse acting, fail open, fail close...)

Convert an actuator from Single Acting to Double Acting configuration and vice versa

Convert a control valve/actuator assembly from a Fail Closed (FC) to a Fail Open (FA) configuration and vice versa

Construct the installation curve for a control valve

Determine flowrate and pressure drop through control valves for different valve lifts

Match the valve characteristics to the given application

Examine the effect of selecting a control valve larger than necessary

Examine the effect of differential pressure on the valve lift and actuator operation

Determine when a positioner should be fitted

...

This will help you develop the necessary skills to ensure your process control systems run smoothly.

Part 3 focuses on fluid properties control. This module identifies different ways in which precise control of temperature, pressure, flow and level is ensured. It provides real industrial examples of process control loops and the keys to interpret them in high quality video lectures. Both self-acting and modulating types of control are discussed in exquisite details.

Part 4 introduces you to advanced process control in process industries. It identifies different ways in which precise control is ensured for the main process equipment such as chemical reactors, pumps, compressors, fired heaters and heat exchangers just to name a few. The numerous examples outlined in this module are taken from petroleum refineries, chemical and steam boiler plants, making the knowledge gained in this section extremely valuable to practicing engineers and technicians.

Part 5 discusses the important concepts of Safety Instrumented Systems (SIS), Alarm Systems and Interlocks. It presents their anatomy, their requirement, their functions and how they are represented in engineering drawings such as Piping & Instrumentation Diagrams.

Part 6 illustrates through 3D animations and cross-sectional views the main control instrument devices to measure temperature, pressure, flow and level. These instruments include thermocouples, RTDs’, Bourdon tube pressure gauges, Coriolis flowmeters, level radars and capillary systems just to name a few...

As you proceed through the masterclass, answer the 400+ question quiz to test your knowledge and emphasize the key learning points.

The quiz includes:

True/False questions

Multi-choice questions

Images, cross-sectional views

Solved problems

And much more...

You have our promise that at after completing this masterclass, you will be an advanced process control professional, you won’t be a process control expert but you will be prepared to become one if that is what you want and persist to be. In fact, the knowledge that you will gain will help you understand all process control loops, instrumentations and safety systems so that you can draw the correct information from them. This will set you apart from your peers, whether you are a graduate student, a practicing engineer or a manager, and will give you an edge over your competitors when seeking employment at industrial facilities.

So with no further ado, check out the free preview videos and the curriculum of the course and we look forward to seeing you in the first section.

Hope to see you there

WR Training

Spread the wings of your knowledge

-----------------------

* When PID is mentioned, it is with reference to Proportional (P), Integral (I) and Derivative (D) control actions

Safety note

Sizing, selection, installation and tuning of process control systems (control valves, actuators, controllers, sensors, wiring...) should not be based on arbitrarily assumed conditions or incomplete information. Merely having a control system does not make a process safe or reliable. Now, while it is obviously impossible to address every installation mistake ever made, we have included a valuable summary of the most frequent installation mistakes encountered in the field. We are confident that this valuable masterclass will help you contribute to the safety of your facility, your fellow workers and yourself.

Bạn sẽ học được gì

Yêu cầu

Nội dung khoá học

Viết Bình Luận

Khoá học liên quan

Đăng ký get khoá học Udemy - Unica - Gitiho giá chỉ 50k!

Get khoá học giá rẻ ngay trước khi bị fix.

Đánh giá của học viên

Bình luận khách hàng